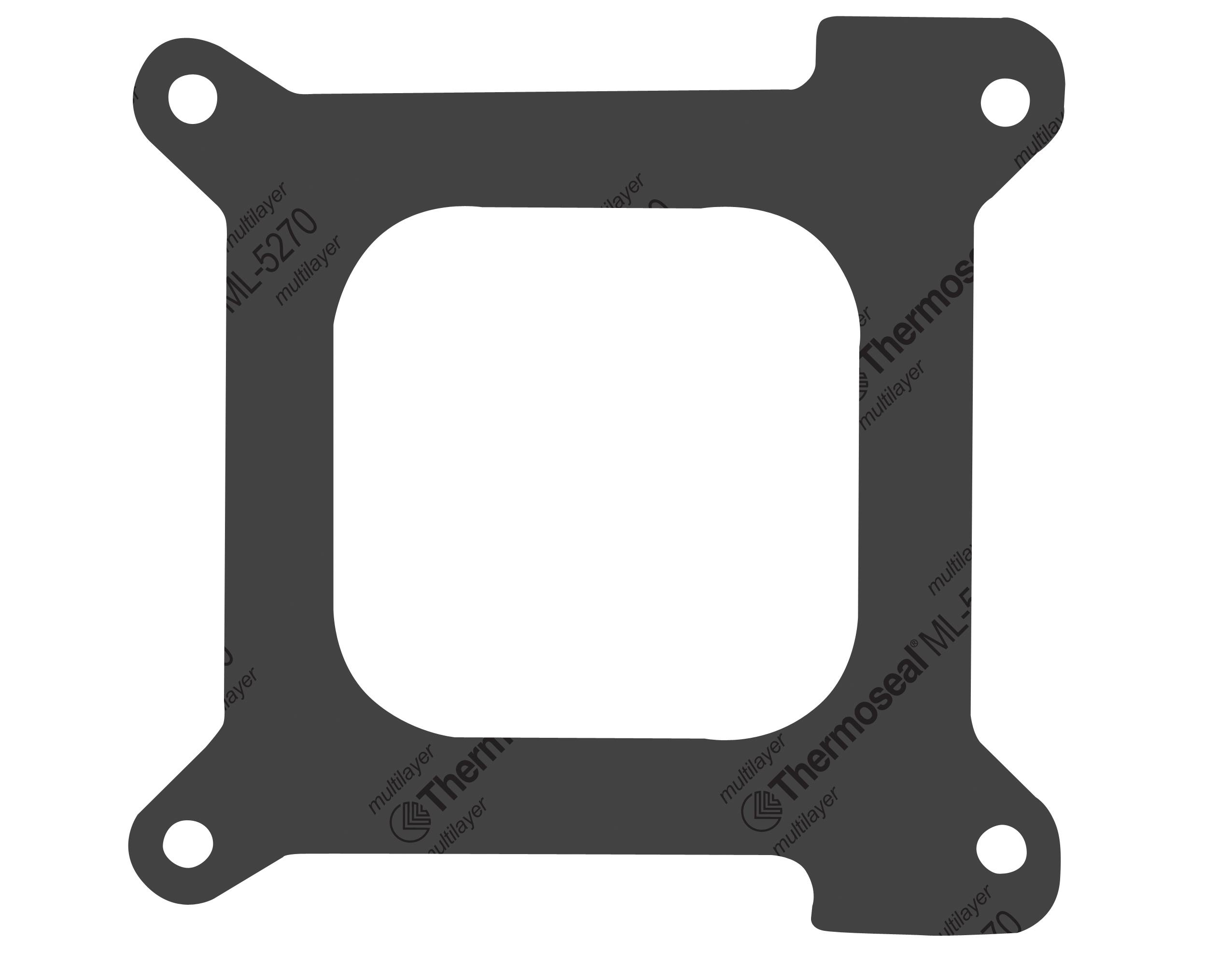

Thermoseal ML-5270

High performance multi-layer sheet

KLINGER Thermoseal's Multi-Layer Technology materials provide both exceptional interfacial and interstitial sealability. Conformable outer layers prevent leakage between the gasket and flanges and a strong high-density core provides structural support while preventing leakage through the gasket.

ML-5270 is a high performance synthetic fiber and polychloroprene binder gasket material that is resistant to refrigerants and oil mixtures. Its unique Multi-Layer Technology structure provides exceptional low flange pressure sealability with exceptional torque retention.

Typical applications include gaskets in hermetic and semi-hermetic compressors and oil pan gaskets in heavy-duty diesel engines with intermittent operating temperatures up to 350°F (177°C).

ML-5270 is a high performance synthetic fiber and polychloroprene binder gasket material that is resistant to refrigerants and oil mixtures. Its unique Multi-Layer Technology structure provides exceptional low flange pressure sealability with exceptional torque retention.

Typical applications include gaskets in hermetic and semi-hermetic compressors and oil pan gaskets in heavy-duty diesel engines with intermittent operating temperatures up to 350°F (177°C).

Typical Values Refer to 1/16" Thick Material Unless Noted

| Temperature maximum | 350°F (177°C) |

| Pressure maximum | 800 psi (5.5 MPa) |

| Density ASTM F1315 | 106 lb/ft (1.7 g/cm³) |

| Compressibility ASTM F36 J | 8 - 14 % |

| Recovery ASTM F36 J | Minimum 40 % |

| Gas Permeability DIN 3535/6 | < 0.3 ml/min |

| Weight Increase ASTM F146 After immersion in Fuel B for 5h/73°F |

Maximum 15 % |

| Thickness Increase ASTM F146 After immersion in Oil IRM 901 for 5h/300°F After immersion in Oil IRM 903 for 5h/300°F After immersion in Fuel B for 5h/73°F |

0 - 5 % maximum 30 % 5 - 0 % |

| Creep relaxation ASTM F38 B (1/32") | Maximum 30 % |

| Sealability ASTM F37 (1/32") | < 0.20 ml/hr |

| Tensile strength ASTM F152 | 2250 psi (15.5 MPa) |

| ASTM F104 Line Call Out | F712241B5K6M6 |

| Color | Black |

The ability of a gasket to make and maintain a seal depends not only on the style and quality of the gasket material, but also on medium being sealed, the flange design, the amount of pressure applied to the gasket by the bolts and how the gasket is assembled onto the flanges and tightened. These factors are beyond the manufacturer's control.