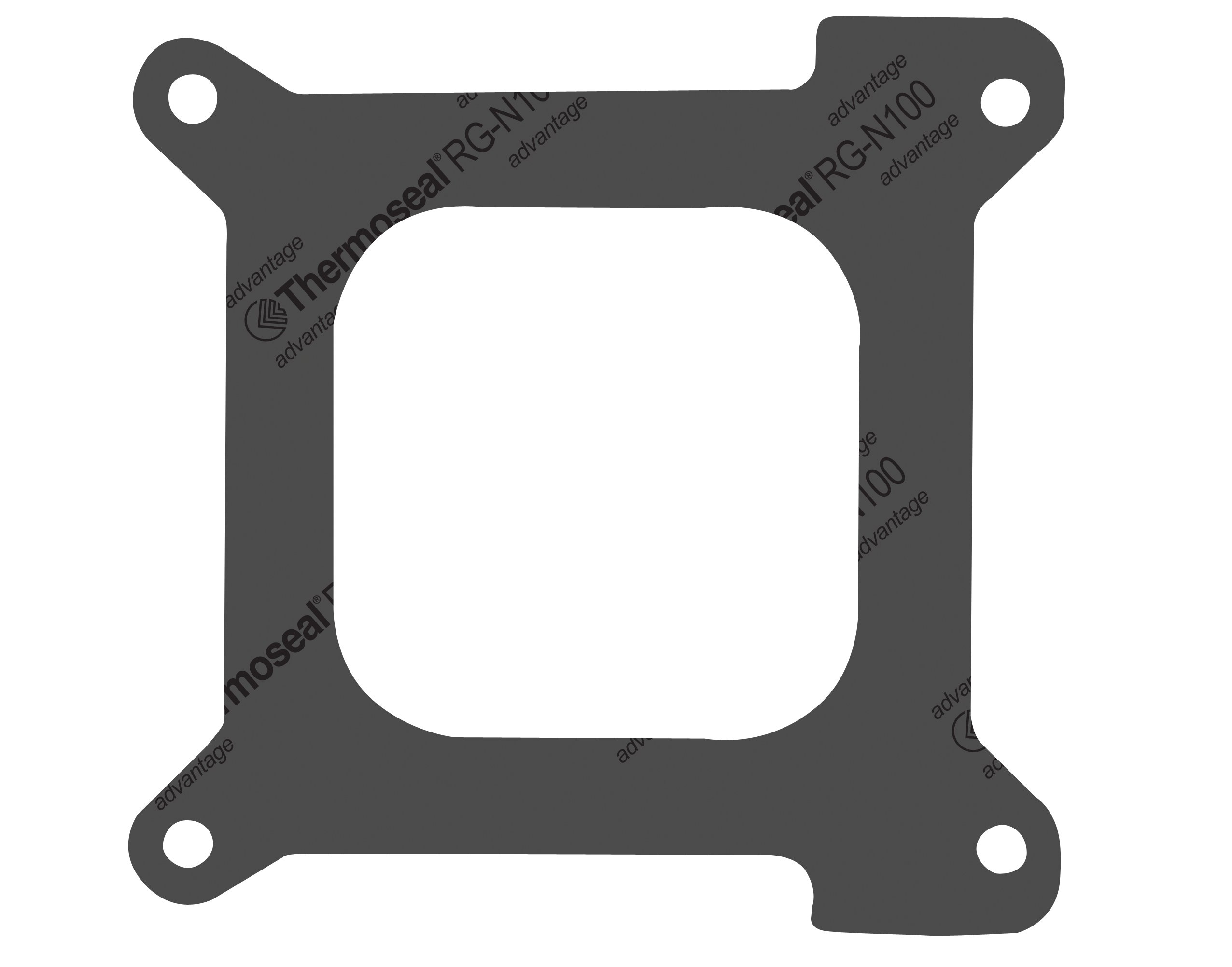

Thermoseal RG-N100

Beater Addition Rolled Goods

KLINGER Thermoseal's Advantage Roll Goods materials perform in a wide range of applications from low-cost aftermarket to higher performing OEM seals. Continuous length rolls allow efficient and economical fabrication with high speed die cutting equipment. When your customers want an "equivalent" or alternative to the currently specified material, there is an Advantage Roll Good for the job.

RG-N100 is a nitrile butadiene rubber, reinforced cellulose fiber and mineral filler general purpose gasket material. Its low density provides good conformability in sealing fuels, oils, and water in applications such as automobile water pumps, miscellaneous cover gaskets, and many small engine applications.

RG-N100 is suitable for applications with intermittent operating temperatures up to 350°F (177°C).

Typical Values Refer to 0.031" Thick Material Unless Noted

| Temperature maximum | 350°F (177°C) |

| Density ASTM F1315 | 62 lb/ft3 (1.0 g/cm³) |

| Compressibility ASTM F36 J | 20 - 40 % |

| Recovery ASTM F36 J | Minimum 30 % |

| Tensile strength ASTM F152 | Minimum 1015 psi (7 MPa) |

| Fluid Resistance after immersion in Fuel B Weight Increase Thickness Increase |

Maximum 40 % Maximum 10 % |

| Fluid Resistance after immersion in Oil IRM903 Weight Increase Thickness Increase |

Maximum 50 % Maximum 10 % |

| Binder Type | Nitrile butadiene rubber |

| ASTM F104 Line Call Out | F729900E99M9 |

| Color | Grey |

The ability of a gasket to make and maintain a seal depends not only on the style and quality of the gasket material, but also on medium being sealed, the flange design, the amount of pressure applied to the gasket by the bolts and how the gasket is assembled onto the flanges and tightened. These factors are beyond the manufacturer's control.