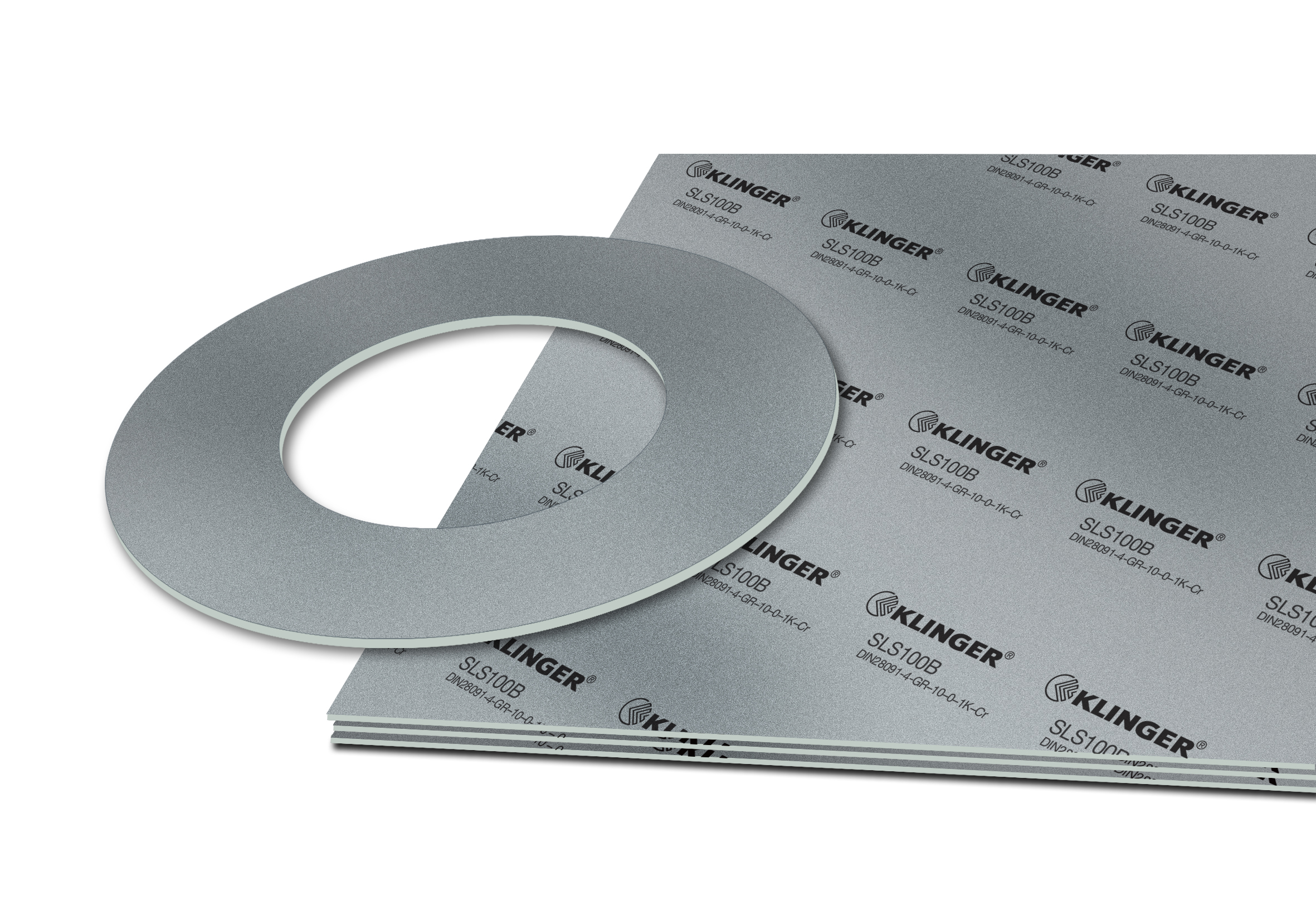

KLINGER® Graphite Laminate SLS

The pure graphite gasket sheet with a smooth stainless steel insert

KLINGER® Graphite Laminate SLS is especially suitable for weak flanges at high temperatures up to 842°F (450°C). The gasket material consists of pure exfoliated layers of graphite, which are mechanically bonded to a 0.05 mm think, smooth, stainless steel insert. The insert aids material handling properties and also increases blow-out resistance. KLINGER® Graphite Laminate SLS is suitable for universal use especially in combination with weak flanges and for sealing of liquid level gauges.

In order to prevent the gasket material from sticking to the flange surface (even at high temperatures), the graphite surface can be given a non-stick coating at the customer's request. With this process, the gasket material's surface is coated and not impregnated.

Typical Values Refer to 2.0 mm Thick Material

| Density DIN28090-2 | 1.0 g/cm³ |

| Purity of Graphite DIN 51903 | ≥ 99.0 % |

| Metallic reinforcement Plain metal Thickness Number of sheets |

AISI 316 (L) 0.05 mm 1 |

| Compressibility ASTM F36A | 35 - 50 % |

| Recovery ASTM F36A | 10 - 15 % |

| Creep relaxation DIN 52913 16h/50 MPa/300°C | ≥ 46 MPa |

| KLINGER Cold/Hot Compression Test 50 MPa Thickness Decrease 23°C Thickness Decrease 300°C |

40 - 50 % 1 - 4 % |

| Specific leak rate DIN 28090-2 | < 0.10 mg/s x m |

| Chloride content of graphite layer DIN 28090-2 | ≤ 40 ppm |

| Color | Grey |

| Non-stick coating | Upon request |

The pressure/temperature graphs shown are the most current method of determining the suitability of a gasket material in a known environment. However, chemical compatibility must also be considered.

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance. Please call or refer to KLINGERexpert for assistance.

In area 3 do not install gaskets in these applications without first referring to KLINGERexpert or contacting KLINGER Thermoseal's technical support service.