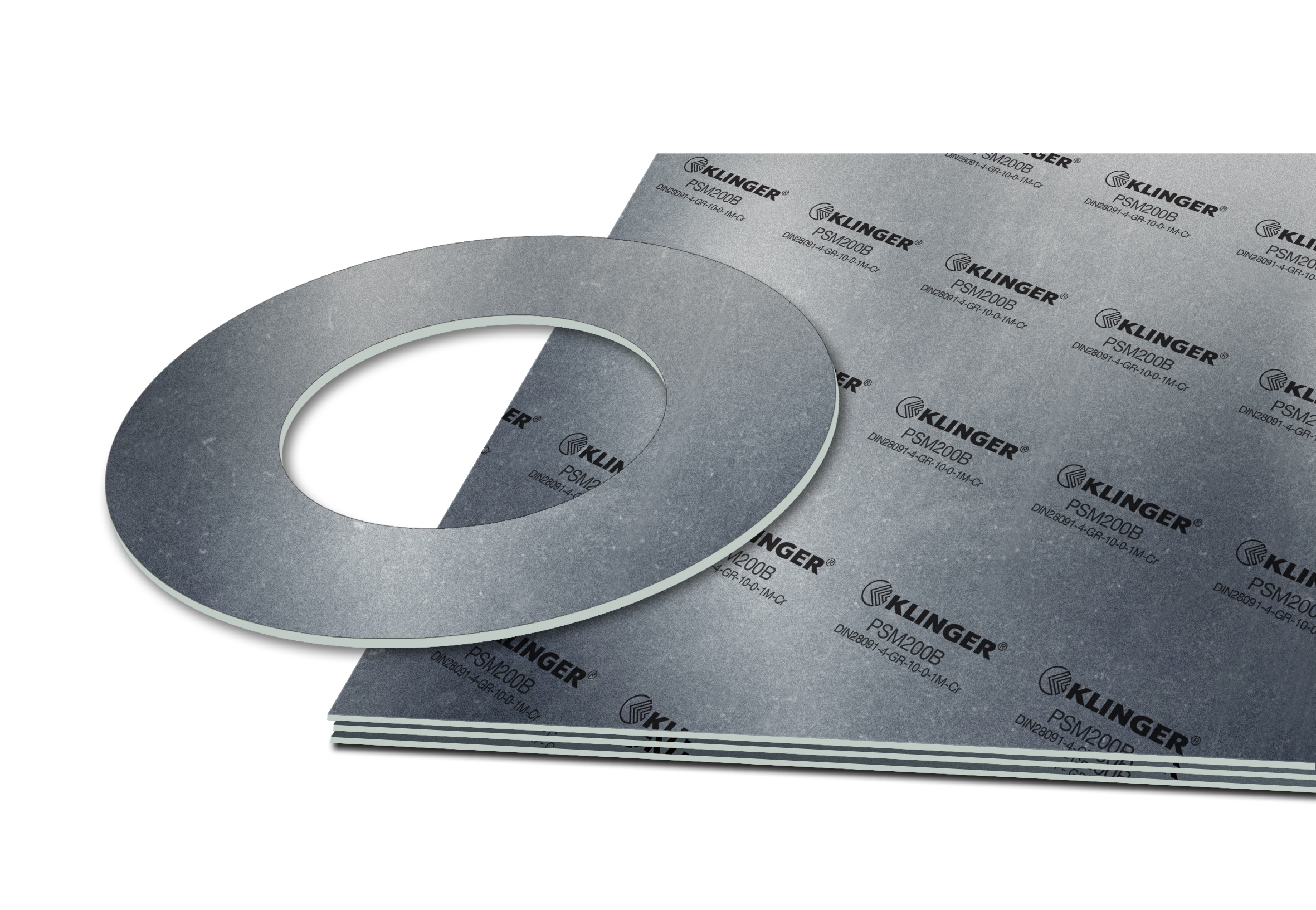

KLINGER® Graphite Laminate PSM

The pure graphite gasket material with a stainless steel tang insert

KLINGER® Graphite Laminate PSM has a 0.1 mm thick perforated stainless steel insert. The insert aids material handling properties and also increases the blow-out resistance. The insert is mechanically bonded to pure exfoliated graphite and therefore does not rely on adhesive.

Stable physical properties over the whole temperature range. KLINGER® Graphite Laminates PSM is suitable for hot water and steam at high temperatures up to 842°F (450°C).

In order to prevent the gasket material from sticking to the flange surface (even at high temperatures), the graphite surface can be given a non-stick coating at the customer's request. With this process, the gasket material's surface is coated and not impregnated.

Typical Values Refer to 2.0 mm Thick Material

| Density DIN28090-2 | 1.0 g/cm³ |

| Purity of Graphite DIN 51903 | ≥ 99.0 % |

| Metallic reinforcement Plain metal Thickness Number of sheets |

AISI 316 (L) 0.05 mm 1 |

| Compressibility ASTM F36A | 35 - 45 % |

| Recovery ASTM F36A | 12 - 18 % |

| Creep relaxation DIN 52913 16h/50 MPa/300°C | ≥ 46 MPa |

| KLINGER Cold/Hot Compression Test 50 MPa Thickness Decrease 23°C Thickness Decrease 300°C |

35 - 45 % 1 - 3 % |

| Specific leak rate DIN 28090-2 | < 0.10 mg/s x m |

| Chloride content of graphite layer DIN 28090-2 | ≤ 40 ppm |

| Color | Grey |

| Non-stick coating | Upon request |

KEY FEATURES & BENEFITS

» Mechanically bonded tanged stainless steel insert

» Free of organic resins or toxic risks

» Excellent chemical resistance

» Excellent high temperature resistance

» Stable physical properties over the whole temperature range

» Provides excellent adaptability to any sealing surface

» Very good tightness

CERTIFICATES AND APPROVALS

» DIN-DVGW

» KTW-Guideline

» Fire-Safe acc. to DIN EN ISO 10497

» German Lloyd

» BAM tested

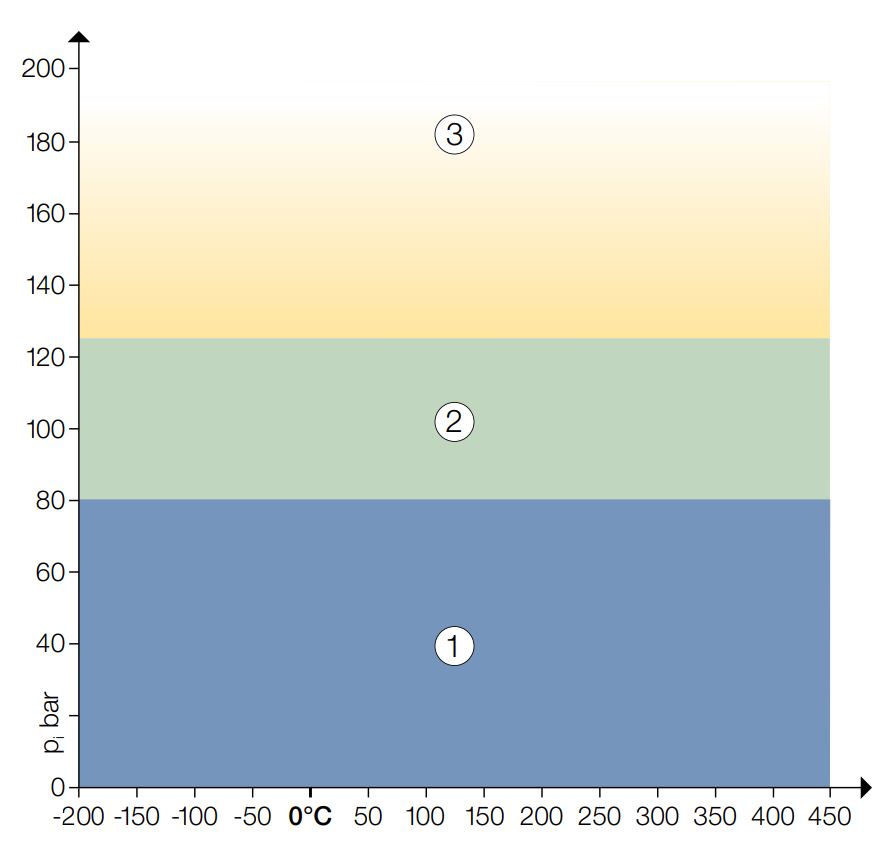

pT diagram for thickness 2.0 mm:

In area 1 the gasket material is suitable using common installment practices subject to chemical compatibility

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance. Please call or refer to KLINGERexpert for assistance.

In area 3 do not install gaskets in these applications without first referring to KLINGERexpert or contacting KLINGER Thermoseal's technical support service.

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance. Please call or refer to KLINGERexpert for assistance.

In area 3 do not install gaskets in these applications without first referring to KLINGERexpert or contacting KLINGER Thermoseal's technical support service.

The ability of a gasket to make and maintain a seal depends not only on the style and quality of the gasket material, but also on medium being sealed, the flange design, the amount of pressure applied to the gasket by the bolts and how the gasket is assembled onto the flanges and tightened. These factors are beyond the manufacturer's control. Please take note of our installation manual in TECHNICAL RESOURCES.