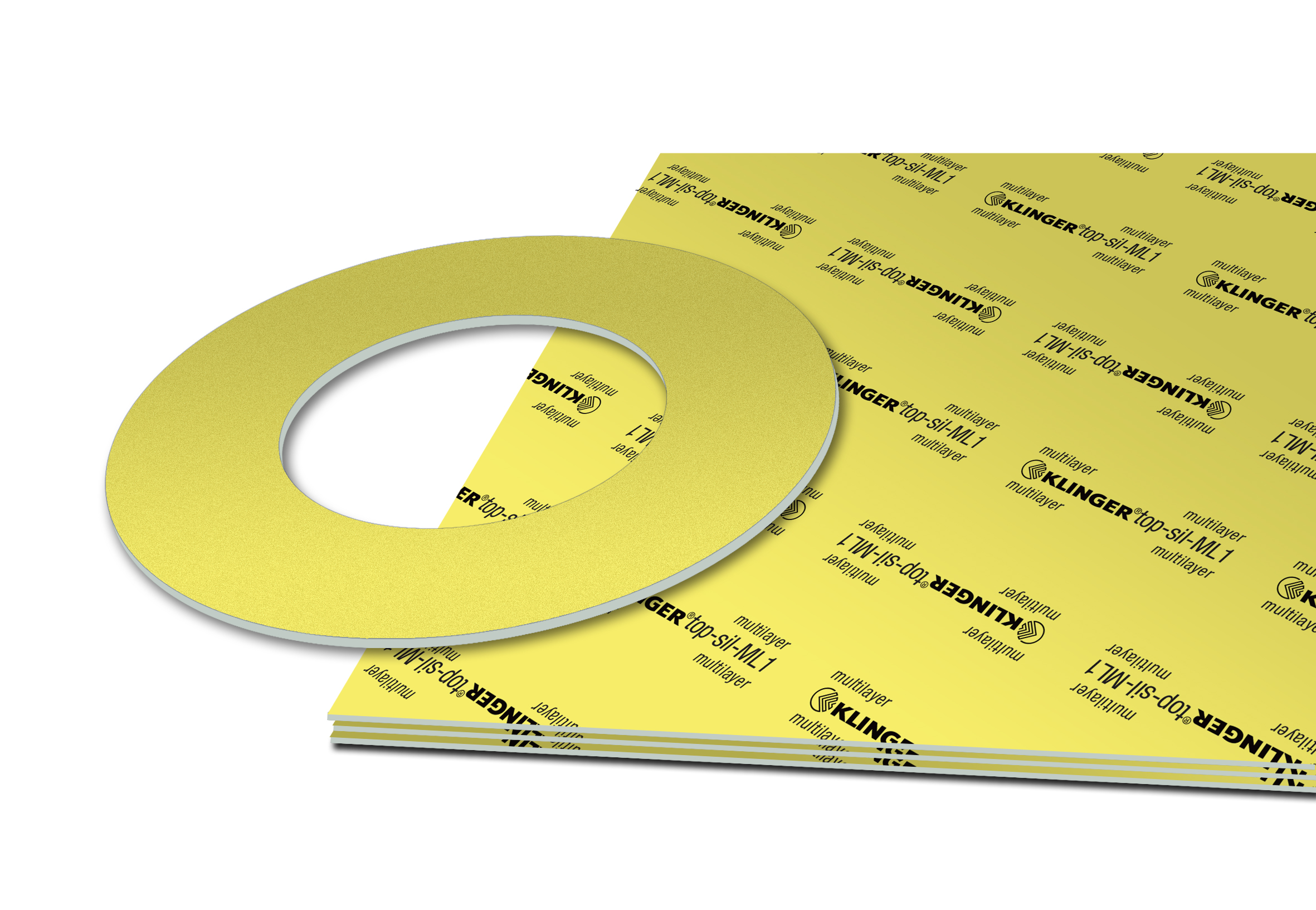

KLINGER®top-sil ML1

Special multi-layer gasket material with extended service life.

KLINGER®top-sil ML1 is a special multi-layer gasket material with extended service life and improved flexibility at higher temperatures. This material is resistant to creep and cold flow and is suitable for use with oils, water, steam, gases, salt solutions, fuels, alcohols, moderate organic and inorganic acids, hydrocarbons, lubricants, and refrigerants.

This material is manufactured with a revolutionary combination of synthetic fibers and HNBR and NBR rubbers, reinforced in a multi-layer structure. This unique multi-layer structure extends service life.

TYPICAL VALUES REFER TO 2.0 MM THICK MATERIAL UNLESS NOTED

| Compressibility ASTM F36J | 8 - 14 % |

| Recovery ASTM F36J | 50 % minimum |

| Stress Relaxation DIN 52913 50 MPa, 16h/347°F (175 °C) 50 MPa, 16h/572°F (300 °C) |

34 MPa 28 MPa |

| Stress Relaxation BS 7531 40 MPa, 16h/572°F (300 °C) |

29 MPa |

| KLINGER Hot Compression Test Thickness Decrease 73°F (23 °C) Thickness Decrease 572°F (300 °C) |

8 % initial 15 % additional |

| Tightness DIN 28090-2 | 0.05 mg/s x m |

| Thickness Increase ASTM F146 after immersion in ASTM Oil IRM 903, 5h/300°F (149°C) ASTM Fuel B, 5h/73°F (23°C) |

0 - 5 % 0 - 10 % |

| Density | 106 lb/ft3 (1.7 g/cc3) |

| Color | Yellow |

CERTIFICATES & APPROVALS

- BAM-tested

- DIN-DVGW

- WRAS approval

- TA-Luft (Clean air)

- Fire-Safe acc. to DIN EN ISO 10497

The pressure/temperature graphs shown are the most current method of determining the suitability of a gasket material in a known environment. However, chemical compatibility must also be considered.

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance. Please call or refer to KLINGERexpert for assistance.

In area 3 do not install gaskets in these applications without first referring to KLINGERexpert or contacting KLINGER Thermoseal's technical support service.